Докритический цикл

Каскадные |

Насосные |

|

|

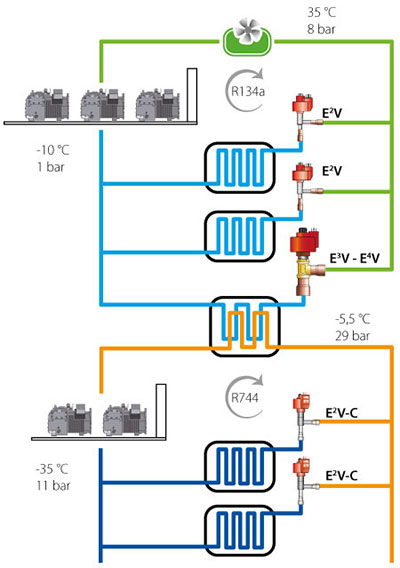

В докритических каскадных системах CO2 используется в качестве хладагента на низкотемпературной стадии (температура всасывания компрессора от -30 до -35°C). Тепло, выделяющееся при конденсации CO2, поглощается хладагентом на среднетемпературной стадии. Данный процесс происходит в каскадном теплообменнике между двумя хладагентами.

|

В докритических насосных системах CO2 используется в качестве хладагента на обеих стадиях (если есть), низкотемпературной и среднетемпературной. В таких системах CO2 выступает в качестве вторичного хладагента, а основной контур, обычно в холодильных машинах с ГФУ/углеводородом, выполняет функцию охлаждения жидкого CO2, который затем насосом подается в систему; данный процесс тоже происходит в теплообменнике, только дополнительно еще имеется приемник жидкости и насос.

|

|

|

|

||

Cascade |

|

|

This solution is ideal for using a natural refrigerant in places with high average temperatures; subcritical CO2 cascade systems are normally used in hot climates or as the first stage in using CO2 as refrigerant. Cascade systems comprise two circuits, one medium temperature (typically R134a, R404a or NH3) and one low temperature (R744), connected via one or more heat exchangers, normally plate exchangers, which on one side condense the CO2 and on the other act as normal evaporators for the medium temperature circuit.. Advantages:

Critical:

|

|

CAREL solution

- pRack pR300 + EXV: the compact CAREL solution for complete control and management of standard compressor racks, designed especially for subcritical CO2 systems; the solution includes a driver for two-pole stepper motors to independently control two electronic expansion valves;

- MPXPRO + E2V: the advanced CAREL Retail System solution for complete and integrated control of multiplexed showcases;

- Ultracap:ensures complete closing of the valves (on the heat exchanger and showcases) even when there are sudden mains power failures.

Pumped |

|

|

The medium temperature showcases are supplied with pumped liquid CO2 while the low temperature showcases are fitted with expansion valves. The CO2 is cooled by a dedicated chiller (NH3 or R134a) inside a tank, normally with a tube bundle evaporator. In addition to traditional systems, these also include pumps that circulate the liquid CO2 to the medium temperature evaporators, where it is not expanded, but rather is simply superheated, returning to the receiver in the semi-liquid phase Advantages:

Critical:

|

|

CAREL solution

- pRack pR300 + EXV:the compact Carel solution for complete control and management of CO2 compressor racks, designed especially for subcritical CO2 systems; the solution includes a driver for two-pole stepper motors to independently control two electronic expansion valves;

- MPXPRO + E2V:the advanced CAREL Retail System solution for complete and integrated control of multiplexed showcases;

- Ultracap:ensures complete closing of the valves (on the heat exchanger and showcases) even when there are sudden mains power failures.